MakroPro 2.0 series

Combining broad customization possibilities with the safety of your business.

Every element of the MakroPro 2.0 series doors is the result of an in-depth analysis of the needs of demanding professionals. The structural solutions unique throughout the market guarantee easy installation and broad possibilities of application in the most diverse types of industrial and public utility buildings.

Characteristics and features

Each element of the MakroPro 2.0 door series was designed with utmost attention to detail, all the while bearing in mind that the ready product will have to face tough requirements. The technological solutions that we used are unique throughout the market and ensure a high degree of safety and durability of the entire design, as well as easy fitting and servicing.

MakroPro 2.0 series

MakroPro 2.0

The MakroPro 2.0 doors are made of 40 [mm] thick warm steel panels infilled with polyurethane foam.

- The standard accessories include the ThermoSet™ gasket kit: four-chamber, double-lip thermal side gaskets; double-lip top gasket; corner gaskets.

- Panel heat transfer coefficient Up = 0.48 [W/m2xK].

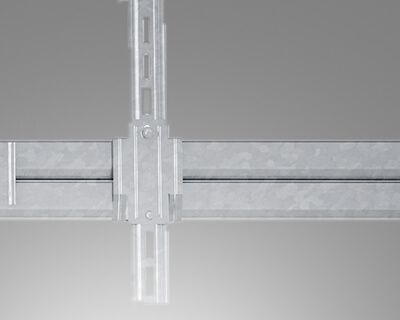

- Thickness of the opening frame 2 [mm] / guide 2 [mm].

- Panel side covers and reinforcements in door leaf colour.

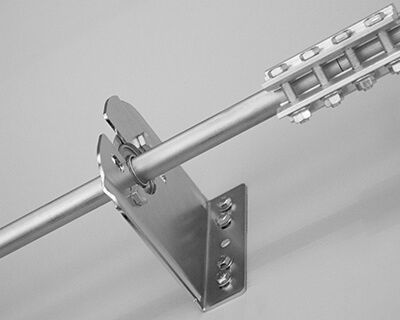

- Quiet guiding rollers with a bush fitting.

- Double safety device for tracks preventing guiding rollers from derailing.

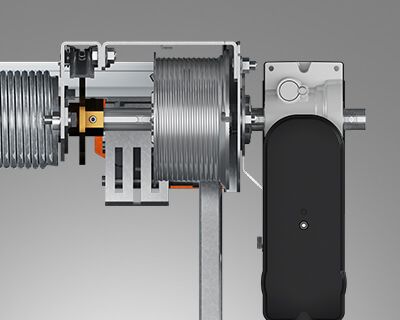

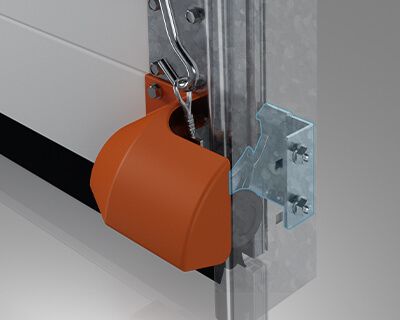

- Protection: cable break safety device (2 pcs.), spring break safety device (per each spring).

- Guaranteed number of cycles 25,000, optionally: 50,000, 100,000, and more than 100,000.

- Watertightness class 2.

- Wind load resistance class 3.

- Air permeability class 4.

- Sound insulation Rw=23/24 [dB] (without a wicket door / with a wicket door).

- Operating noise of the door: 24/36 [dB] (with an electric drive unit 8.60 FU / SE9).

- Reaction to fire NFP: B, s2, d0.

- The manually-operated door is fitted with a sliding bolt.

MakroPro 2.0 series

MakroPro ALU 2.0

The doors are made of 40 [mm] thick aluminium panels without a thermal break, infilled with acrylic glazing. Steel bottom panel.

- The standard accessories include the ThermoSet™ gasket kit: four-chamber, double-lip thermal side gaskets; double-lip top gasket; corner gaskets.

- Thickness of the opening frame 2 [mm] / guide 2 [mm].

- Panel reinforcement in the door leaf colour.

- Quiet guiding rollers with a bush fitting.

- Double safety device for tracks preventing guiding rollers from derailing.

- Protection: cable break safety device (2 pcs.), spring break safety device (per each spring).

- Guaranteed number of cycles 25,000, optionally: 50,000, 100,000, and more than 100,000.

- Watertightness class 2.

- Wind load resistance class 3.

- Air permeability class 4.

- Sound insulation Rw=23/25 [dB] (without a wicket door / with a wicket door).

- Reaction to fire NFP: B, s2, d0.

- The manually-operated door is fitted with a sliding bolt.

MakroPro 2.0 series

MakroPro 2.0 ALU ISO

The doors are made of 40 [mm] thick aluminium panels with a thermal break, infilled with acrylic glazing. Steel bottom panel.

- ThermoSet™ gasket kit: four-chamber, double-lip thermal side gaskets; double-lip top gasket; corner gaskets.

- Heat transfer coefficient – as provided on the door nameplate.

- Thickness of the opening frame 2 [mm] / guide 2 [mm].

- Panel reinforcement in the door leaf colour.

- Quiet guiding rollers with a bush fitting.

- Double safety device for tracks preventing guiding rollers from derailing.

- Protection: cable break safety device (2 pcs.), spring break safety device (per each spring).

- Guaranteed number of cycles 25,000, optionally: 50,000, 100,000, and more than 100,000 cycles. - Watertightness – class 3. - Air permeability – class 4.

- Sound insulation Rw=23 [dB].

- Wind load resistance – class 4.

- The manually-operated door is fitted with a sliding bolt.

MakroPro 2.0 ELH

Façade door

The MakroPro 2.0 ELH door was designed so that it can be complemented with an individual infill. This means that its leaf on the outside may look exactly the way the designer or investor expects it to.

The possibilities are almost unlimited. The front covered with tiles, slate or plastic panels? Why not integrate the door with the background – to create the effect of a perfectly uniform façade? This provides a multitude of possibilities to architects and enterprises wanting to highlight their dedication to and appreciation for beauty.

Colour scheme

Do you prefer classic style? Or are you planning to choose something unobvious? Our colour and film coating palette gives you almost unlimited possibilities.

- Standard colours

- Film coatings, special colours

Textures

We choose the texture of the gate using two senses: touch and vision. Select it so that it looks amazing from every perspective.

Inspiration

Get inspired by our completed projects and choose a industrial door matching your style and needs.

Product catalogues

Find inspiration in the possibilities provided by WIŚNIOWSKI garage doors, gates, windows, doors, and fences. The catalogues present the best completed projects and plenty of great tips and advice.

Technical Data Sheets

Discover the details of our products. The Technical Data Sheets provide information on the dimensions, types of installation, and installation conditions. Plan your investment with attention to every detail.